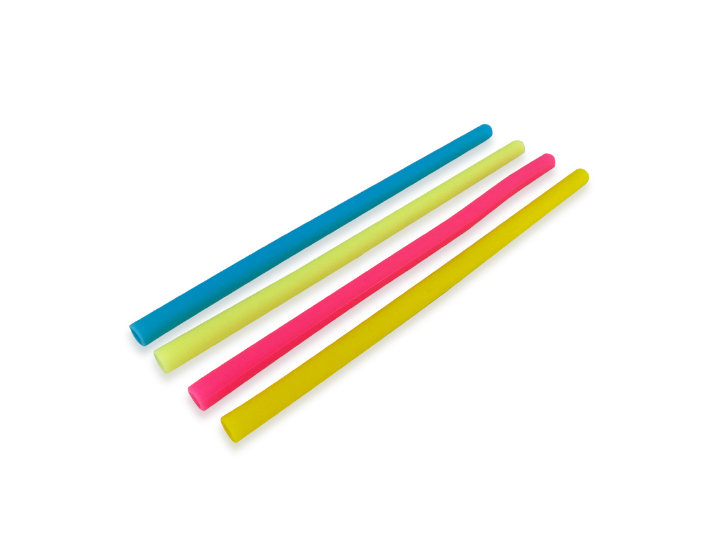

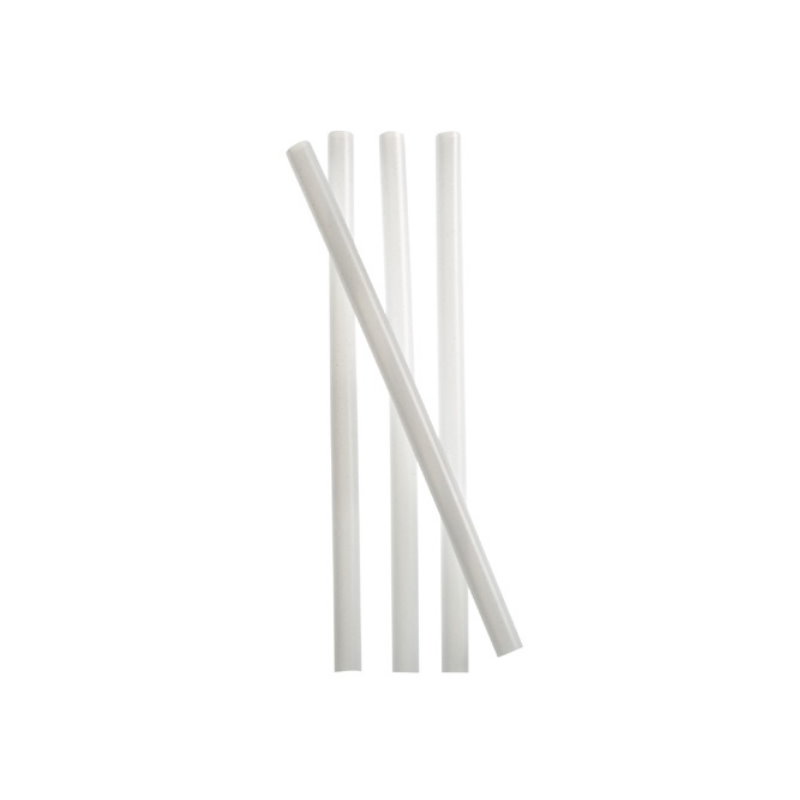

Silicone tubes are divided into Food grade silicone tubes, industrial grade silicone tubes, medical grade silicone tubes and so on in our life and workplace.

1.Food grade silicone tube: It is widely used in machinery, electrical appliances, electricity and other industries with mechanical products, such as coffee pots, water heaters, bread maker, disinfection cabinets, water dispensers, kettles, irons, rice cookers, frying pans, pulpers, gas appliances, and so on. With the characteristic of high temperature resistance, does not decompose any smell and taste, corrosion resistance, and so on, that can easily adapt into lives, it can be used in water dispenser, protective covers for coffee pots, hairdressing equipent and lighting accessories.

2. Industrial grade silicone tube: It is made to withstand repeated compression and release, and its reliability is much stronger than that of standard silicone tubes, and have higher stability. It is generally suitable for sucking in and outputting all kinds of high-quality milk, oil and fatty foods, which effectively maintains the cleanliness of the products and achieves a greater level of pollution-free.

3.Medical grade silicone tube: It is produced from inorganic polymer colloidal material made by silicic acid polycondensation. The main component is SiO2*nH2O with a content of more than 98%. It is non-toxic, odorless, and chemically stable, which does not react with any acid salts in normal condition except sodium hydroxide and hydrofluoric acid. The pharmaceutical silicone tube provides a balanced solution flow, which also effectively inhibits bacterial growth, and tolerates continuous peristaltic suction that effectively improves pharmaceutical efficiency.

Industrial grade silicone tube – protect machinery and electrical appliances, protect the environment, and protect the quality of our lives!

Industrial grade silicone tubes are not only important components in the modern industry, but also the first eco-friendly tube products in the industrial tubes. Eco-friendly tubes are mainly used as wires, cables, wire and cable protection tubes for automated instrumentation signals, and showering tubes for daily life, with the specifications range from 3mm to 150mms. Tubes with small diameters (inner diameter 3mm-25mm) are mainly used for the protection of the sensing circuit of the precision optical ruler and the industrial sensor circuit.

The industrial grade silicone eco-friendly tubes have been added with new materials which make them non-toxic and odorless. The tubes have good elasticity, anti-torsion, good bending ability that can withstand heavy loads, and is resistant to acid, lubricating oil, coolant and so on, with polished and friction-resistant surfaces. It has the advantage of withstanding heavy pressure of foot tapping, does not break or deform, and can quickly restore without damaging that is generally using for wire and cable protection in machinery manufacturing, electrical wiring insulation protection tube, lighting equipment, automobile manufacturing, aviation equipment, subway, train, automation control and so on. Thus, the eco-friendly tubes play an important role and are inseparable with our daily life.

The configuration characteristics of high temperature resistant silicone tube equipment are as follows:

1. The high temperature resistant silicone tube adopts industrial grade or above accessories, oil lubricated ceramic high pressure plunger pump (with oil level window) and high-functioning bypass control stepless pressure regulating valve (to adapt to different cleaning tasks), high reliability and long service life;

2. It has a simple electrified operation, which can be switched between cold, hot, steam, while using high-pressure cleaning the high temperature resistant silicone tube. The intelligent temperature controller can accurately control the water temperature, and the leakage protection design ensures the safety of users;

3. It has a heavy and tough steel structure frame, which can adapt to harsh indoor working or field working environment, and has a high safety factor;

4. With strong and high-functioning motor, direct connection and coupling connection can be adopted, the motor ingression protection rating is IP55 and IP54, and it is air-cooled;

5. At the same time, sandblasting kit and cleaning agent adding device can be selected. Mixed wet sandblasting can quickly remove rust and paint;

6. It has heavy-duty tires, stainless steel shock-proof pressure gauge, and precision water inlet filter device;

7. The high temperature resistant silicone tube also adopts the advanced fringe coil type alloy coil design, which greatly improves the heating efficiency and service life. The industrial grade stainless steel heating furnace with thermal efficiency greater than 93% can generate a steady stream of high-pressure hot water within a few seconds with low fuel consumption;

![]()

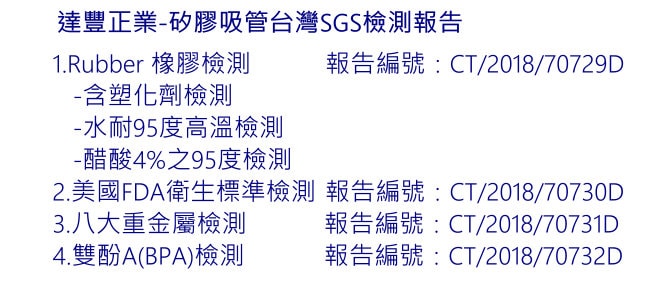

Dafeng Integrity – silicone tubes from our customized silicone factory have passed the tests of Taiwan SGS as shown in the following:

1.Four major inspection items for silicone tubes:

a.Rubber inspection (the inspections of silicone products in Taiwan refer to those for rubber products, which contain the plasticizer testing.)

b.U.S. FDA healthy standard inspection

c.Inspection of eight major heavy metals

d.Bisphenol A (BPA) inspection (silicone products in Taiwan do not have BPA specifications, this item refers to PPSU feeding bottle specifications.)

2.Other important inspection items:

a.High temperature resistance in 95ºC water detection (for high temperature hot drinks)

b.4% acidic acid in 95ºC detection (for acidic beverages)

c.Provide Chinese, English, and Chinese/English test reports (for letting the public understand)

d.Provide a QR code, which can be linked to the SGS online platform for browsing (for public inquiry)

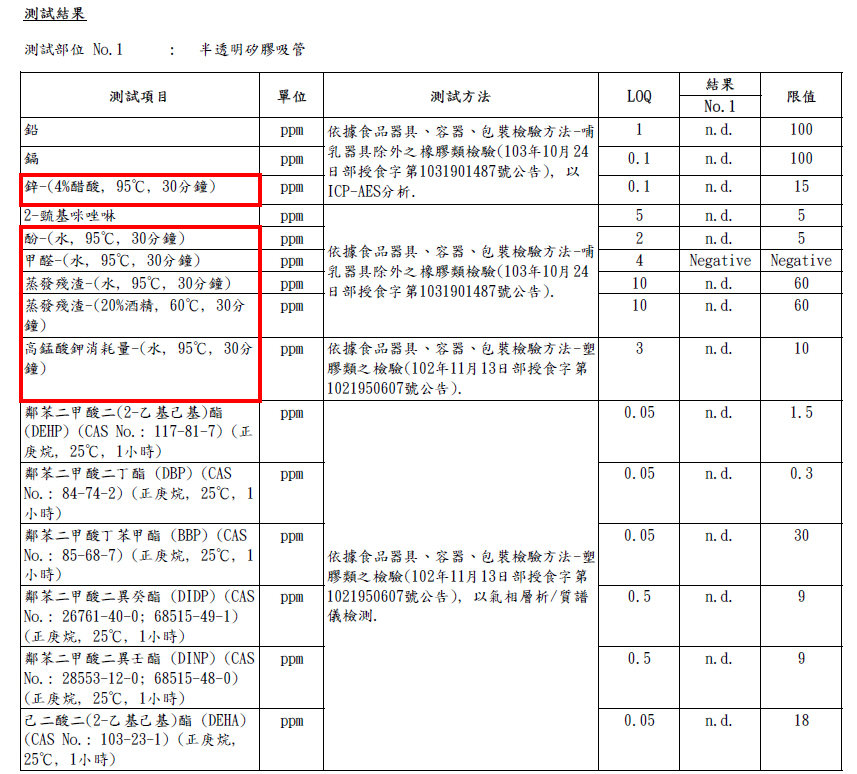

| No | 檢測項目 | 檢測內容 | 結果 |

| 1 | Rubber 橡膠檢測

-含塑化劑檢測 -水耐95度High溫檢測 -醋酸4%之95度檢測 |

鉛、鎘、鋅-(4%醋酸, 95℃, 30分鐘)

2-巰基咪唑啉 酚-(水, 95℃, 30分鐘) 甲醛-(水, 95℃, 30分鐘) 蒸發殘渣-(水, 95℃, 30分鐘) 蒸發殘渣-(20%酒精, 60℃, 30分鐘) High錳酸鉀消耗量-(水, 95℃, 30分鐘 鄰苯二甲酸二(2-乙基己基)酯(DEHP)(正庚烷, 25℃, 1小時) 鄰苯二甲酸二丁酯 (DBP) (CASNo.: 84-74-2) (正庚烷, 25℃, 1 小時) 鄰苯二甲酸丁苯甲酯 (BBP) (CASNo.: 85-68-7) (正庚烷, 25℃, 1 小時) 鄰苯二甲酸二異癸酯 (DIDP) (CASNo.: 26761-40-0; 68515-49-1) (正庚烷, 25℃, 1小時) 鄰苯二甲酸二異壬酯 (DINP) (CASNo.: 28553-12-0; 68515-48-0) (正庚烷, 25℃, 1小時) 己二酸二(2-乙基己基)酯 (DEHA)(CAS No.: 103-23-1) (正庚烷, 25℃, 1小時) 重金屬(以鉛計)-(4%醋酸, 95℃,30分鐘) 鄰苯二甲酸二(2-乙基己基)酯(DEHP) 鄰苯二甲酸二丁酯 (DBP) 鄰苯二甲酸丁苯甲酯 (BBP) 鄰苯二甲酸二正辛酯 (DNOP) 鄰苯二甲酸二異壬酯 (DINP) 鄰苯二甲酸二甲酯 (DMP 鄰苯二甲酸二異癸酯 (DIDP) 鄰苯二甲酸二乙酯 (DEP) |

全部未檢出 |

| 2 | FDA(美國)衛生標準檢測 | 總萃取物 (水, 迴流, 前7小時)

總萃取物 (水, 迴流, 接續2小時) 總萃取物 (正己烷, 迴流, 前7小時) 總萃取物 (正己烷, 迴流, 接續2小時) |

通過 |

| 3 | 八大重金屬檢測 | 銻、砷、鋇、鉻、鎘、鉛、汞、硒 | 全部未檢出 |

| 4 | pairs酚A(BPA)材質檢測 | pairs酚A(BPA) | 全部未檢出 |

如何判斷檢驗報告真的為台灣SGS檢測單位所發出報告?

1.看其報告號碼編號是否為台灣編號?

2.看其檢驗證明章是否為TAIWAN?

3.看其檢驗報告詳細內容是否符合四大檢測項目?

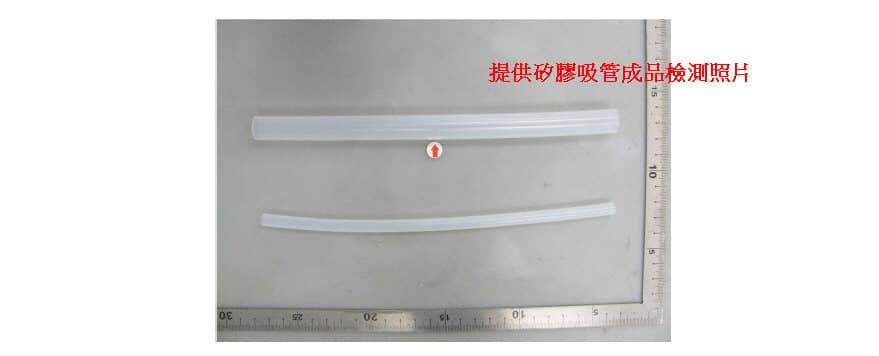

4.看其檢測報告是否有附矽膠吸管成品檢測照片?