Silicone plugs are flame-resistant, heat-resistant, moisture-resistant, water-resistant and have good electrical insulation.

To order, please click here to contact us

Silicone is a polymer between organic and inorganic. It consists mainly of silica, which is chemically stable and non-flammable. Silicone has high thermal stability that can withstand extreme temperatures from -40 ºC to 230 ºC with a heat resistance up to 260 ºC.

Silicone is a highly activated adsorption material, which is an amorphous substance that can vary in consistency from liquid to gel to grease or to elastomer. It is insoluble in water or any solvent that is non-toxic, odorless and chemically stable. Silicone does not react with any substances except strong base and hydrofluoric acid, which demonstrates the irreplaceable benefits comparing to other similar materials: high adsorption performance, good thermal stability, stable chemical properties, and high mechanical strength, etc. Products made of silicone can be seen in daily necessities, kitchenware, sporting goods, baby products, beauty and health care products, and so on, in our daily life, and Dafeng integrity provides you with the best silicone customization options.

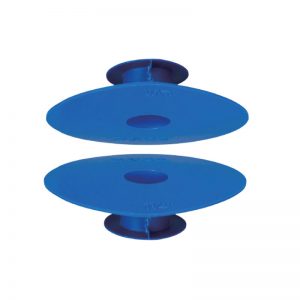

Introduction of silicone plugs

One of the reasons choosing silicone products might be having specific requirements for high temperature resistance, for example, commonly used silicone plugs would sometimes need to be used in different environments with high and low temperature resistance.

Different silicone plugs aimed at specific industries can be roughly divided into several types, and can also be limited to the temperature resistance conditions of the silicone itself.

For example, silicone through hole plus for though holes, silicone stopper plugs, and countersunk threaded type high-temperature resistant plugs, are three different types of plugs used in different fields, which lead to different temperature resistance effects as the selection of product materials and thicknesses varied depending on the fields they are used in. Comparing to the other two, the selection of through hole plugs is relatively standardized, which has good high temperature resistance. If considered to increase the effect of high temperature resistance, it is encouraged to use the gas chromatography technique to increase the density of the raw materials. As to the reasons of the relatively lower high temperature effect of stopper and threaded type plugs are due to the differences in shape and structures, which caused the faster sensation when contacting to high temperatures. Literally, through hole plugs products are hollow with simple structures that have think wall thicknesses without any internal complexity; while the stopper and threaded type plugs have uneven and complex product structures, which bring higher apparent temperature that supports the heat transfer. Although conventional test of the high and low temperature resistance of silicone products is still -40°C to 230°C, with the structure of silicone products and the characteristics of raw materials, this limitation may be overfulfill and achieve better temperature resistance. As for the temperature resistance performance of silicone plugs, normal high temperature resistance can still overfulfill the usage limits!

Method of cleaning for silicone plugs:

- Clean water: silicone plugs can be rinsed with water. If the plugs are left on greasy dirt, apply soap and then rinse the silicone plugs with water. Silicone plugs can be dried directly using the air heater. Do not expose to the sun. Although silicone is a strong anti-corrosion material, it turns yellow with prolonged exposure to the sun. Note: Do not frequently wash the plugs, otherwise they will turn yellow.

- Alcohol cleaning: before cleaning silicone plugs, use alcohol cotton to clean it. Note that the cotton swab should be made of wood or bamboo, not plastic. Use soft cotton clothes with alcohol to gently wipe through the silicone plugs.

- Use an eraser: the dirt on silicone plugs can be cleaned up using erasers. With minor dirt on the silicone plug, try wiping it with an eraser several times, and then rinse it with water, which brings good cleaning result. If the erasers couldn’t solve the yellowing problem on the plugs, try using toothpaste, which is also a very effective cleaning tool.

Silicone plugs |

Push-in plugs |

Protective caps |

|---|---|---|

S1421NE01-Heat-resistant tapered plug |

S1421NP04-Red cap plug |

S1421NP14-Straight edge cap |

S1421NE02-Heat-resistant pull plug |

S1421NP05-Red wide-edged cap plug |

S1421NP15A-Easy-fit/flip cap with ring pull |

S1421NE03-Heat-resistant flangeless threaded plug |

S1421NP06A-Drum plug |

S1421NP15B-Grease nipples with retaining tap |

S1421NE04-Heat-resistant washer plug |

S1421NP06B-Parallel protection plug |

S1421NP15C-Long bolt protection cap |

S1421NE05-Heat-resistant conical plug |

S1421NP07A-Push-in plug with lateral pull tab |

S1421NP16A-Bolt and nut protection cap |

S1421NE06-Heat-resistant flangeless pull tapered plug |

S1421NP07B-Yellow wide-edged tapered cap plug |

S1421NP16B-Yellow pull-tab cap |

S1421NE07-Heat-resistant gasket pull plug |

S1421NP08A-Black rubber cap plug |

S1421NP16C-Blue pipe and tube protection cap |

S1421NE08-Rat tail plug |

S1421NP08B-Centered pull-tab plug |

S1421NP17A-Black pipe and tube plastic cap |

S1421NE09-Heat-resistant flangeless corrugated plug |

S1421NP09A-Transparent tapered plug |

S1421NP17B-End protection cap |

S1421NE10-Hollow threaded handle plug |

S1421NP09B-Lateral pull-tab plug |

S1421NP17C-Inner fin bolt cap |

S1421NE11-Double headed plug |

S1421NP09C-Small side pull-tab plug |

S1421NP18A-Long round flexible soft cap |

S1421NE12-Double gasket threaded plug |

S1421NP10A-Parallel rubber plug |

S1421NP18B-Flexible soft cap with pull handle |

S1421NE13-Heat-resistant protection cover |

S1421NP10B-Red threaded push-in plug |

S1421NP19A-Rectangular flexible soft cap |

S1421NE14-Gasket protection cover |

S1421NP10C-Solid plug |

S1421NP19B-Square flexible soft cap |

S1421NP10D-Yellow pull-tab plug |

S1421NP20A-Wide flange cover |

|

S1421NP11A-Rubber handle plug |

S1421NP20B-Raised face flange protectors with mounting tab |

|

S1421NP11B-Silicone water stopping plug |

S1421NP20C-SAE hexagonal flange protection |

|

S1421NP12A-Groove-headed plug |

S1421NP21A-Small flange protective cover |

|

S1421NP13A-RJ interface plug |

S1421NP21B-Blue flange cover |

|

S1421NP13B-Round cover plug |

S1421NP21C-Driveshaft protection cap |

|

Screw cap plug |

Pipe plug |

|

S1421NP22-Slotted thread sealing plug |

S1421NP35A-Oval tube plug |

|

S1421NP23A-Threaded fitting plug |

S1421NP35B-Square tube plug |

|

S1421NP23B-Threaded internal caps with hexagonal head and assembled O-ring |

S1421NP36A-Chromium surface round tube plug |

|

S1421NP24A-Round-headed thread plug |

S1421NP36B-Rectangular tube plug |

|

S1421NP24B-Yellow hexagonal screw threaded plug |

S1421NP37A-Round tube plug |

|

S1421NP25A-Metal threaded plug |

S1421NP37B-Light round tube plug |

|

S1421NP25B-Inner hexagonal threaded plug |

S1421NP38A-Shrapnel threaded pipe connector |

|

S1421NP26A-Taper pipe threaded plug |

S1421NP38B-Desk cable hole plug |

|

S1421NP26B-Red threaded cap |

S1421NP39A-Plastic thread round pipe plug |

|

S1421NP27-Threaded sealing cap with gasket |

S1421NP39B-Plastic thread square pipe plug |

Silicone is a polymer between organic and inorganic. It consists mainly of silica, which is chemically stable and non-flammable. Silicone has high thermal stability that can withstand extreme temperatures from -40 ºC to 230 ºC with a heat resistance up to 260 ºC.

Silicone is a highly activated adsorption material, which is an amorphous substance that can vary in consistency from liquid to gel to grease or to elastomer. It is insoluble in water or any solvent that is non-toxic, odorless and chemically stable. Silicone does not react with any substances except strong base and hydrofluoric acid, which demonstrates the irreplaceable benefits comparing to other similar materials: high adsorption performance, good thermal stability, stable chemical properties, and high mechanical strength, etc. Products made of silicone can be seen in daily necessities, kitchenware, sporting goods, baby products, beauty and health care products, and so on, in our daily life, and Dafeng integrity provides you with the best silicone customization options.

Introduction of silicone plugs

One of the reasons choosing silicone products might be having specific requirements for high temperature resistance, for example, commonly used silicone plugs would sometimes need to be used in different environments with high and low temperature resistance.

Different silicone plugs aimed at specific industries can be roughly divided into several types, and can also be limited to the temperature resistance conditions of the silicone itself.

For example, silicone through hole plus for though holes, silicone stopper plugs, and countersunk threaded type high-temperature resistant plugs, are three different types of plugs used in different fields, which lead to different temperature resistance effects as the selection of product materials and thicknesses varied depending on the fields they are used in. Comparing to the other two, the selection of through hole plugs is relatively standardized, which has good high temperature resistance. If considered to increase the effect of high temperature resistance, it is encouraged to use the gas chromatography technique to increase the density of the raw materials. As to the reasons of the relatively lower high temperature effect of stopper and threaded type plugs are due to the differences in shape and structures, which caused the faster sensation when contacting to high temperatures. Literally, through hole plugs products are hollow with simple structures that have think wall thicknesses without any internal complexity; while the stopper and threaded type plugs have uneven and complex product structures, which bring higher apparent temperature that supports the heat transfer. Although conventional test of the high and low temperature resistance of silicone products is still -40°C to 230°C, with the structure of silicone products and the characteristics of raw materials, this limitation may be overfulfill and achieve better temperature resistance. As for the temperature resistance performance of silicone plugs, normal high temperature resistance can still overfulfill the usage limits!

Method of cleaning for silicone plugs:

- Clean water: silicone plugs can be rinsed with water. If the plugs are left on greasy dirt, apply soap and then rinse the silicone plugs with water. Silicone plugs can be dried directly using the air heater. Do not expose to the sun. Although silicone is a strong anti-corrosion material, it turns yellow with prolonged exposure to the sun. Note: Do not frequently wash the plugs, otherwise they will turn yellow.

- Alcohol cleaning: before cleaning silicone plugs, use alcohol cotton to clean it. Note that the cotton swab should be made of wood or bamboo, not plastic. Use soft cotton clothes with alcohol to gently wipe through the silicone plugs.

- Use an eraser: the dirt on silicone plugs can be cleaned up using erasers. With minor dirt on the silicone plug, try wiping it with an eraser several times, and then rinse it with water, which brings good cleaning result. If the erasers couldn’t solve the yellowing problem on the plugs, try using toothpaste, which is also a very effective cleaning tool.

Model |

Dimensions (mm) |

Thread |

Type |

||||

d1 |

d2 |

H |

Metric thread |

American thread |

Imperial thread |

||

SCP01-1.6-0.4-15.9 |

1.6 |

0.4 |

15.9 |

– |

– |

– |

Solid |

SCP02-2-0.5-19.1 |

2 |

0.5 |

19.1 |

M2 |

– |

– |

Solid |

SCP03-2-0.5-25.4 |

2 |

0.5 |

25.4 |

|

|

|

Solid |

SCP04-3.2-0.8-15.9 |

3.2 |

0.8 |

15.9 |

M2 |

– |

– |

Solid |

SCP05-3.2-1.6-15.9 |

3.2 |

1.6 |

15.9 |

M3 |

– |

– |

Solid |

SCP06-4.8-1.6-15.9 |

4.8 |

1.6 |

15.9 |

M3, M4 |

– |

– |

Solid |

SCP07-4.8-1.6-19.1 |

4.8 |

1.6 |

19.1 |

M3, M4 |

– |

– |

Solid |

SCP08-5.5-1.2-38.1 |

5.5 |

1.2 |

38.1 |

M3, M4, M5 |

– |

– |

Solid |

SCP09-6.4-3.2-19.1 |

6.4 |

3.2 |

19.1 |

M5, M6 |

1/4〃 |

– |

Solid |

SCP10-6.4-3.2-25.4 |

6.4 |

3.2 |

25.4 |

M5, M6 |

1/4〃 |

– |

Solid |

SCP11-7-4-20 |

7 |

4 |

20 |

– |

– |

– |

Solid |

SCP12-7-3-25 |

7 |

3 |

25 |

– |

– |

– |

Solid |

SCP13-7.1-1.7-38 |

7.1 |

1.7 |

38 |

– |

– |

– |

Solid |

SCP14-8.7-4.8-15.9 |

8.7 |

4.8 |

15.9 |

M7, M8 |

5/8〃 |

1/16〃 |

Solid |

SCP15-8.7-4.8-25.4 |

8.7 |

4.8 |

25.4 |

M7, M8 |

5/8〃 |

1/16〃 |

Solid |

SCP16-9.2-6.2-12.8 |

9.2 |

6.2 |

12.8 |

M8 |

5?8〃 |

1/8〃 |

Solid |

SCP17-9.2-3.2-31.8 |

9.2 |

3.2 |

31.8 |

– |

– |

– |

Solid |

SCP18-9.5-6.5-18.5 |

9.5 |

6.5 |

18.5 |

M8 |

5/8〃 |

1/8〃 |

Solid |

SCP19-9.5-6.4-12.7 |

9.5 |

6.4 |

12.7 |

M10 |

3/8〃 |

1/8〃 |

Solid |

SCP20-9.5-6.4-19.1 |

9.5 |

6.4 |

19.1 |

M10 |

3/8〃 |

1/8〃 |

Solid |

SCP21-10-6-20 |

10 |

6 |

20 |

– |

– |

– |

Solid |

SCP22-10.5-6.5-25.4 |

10.5 |

6.5 |

25.4 |

– |

– |

– |

Solid |

SCP23-11-8.5-17.5 |

11 |

8.5 |

17.5 |

M10 |

3/8〃 |

– |

Solid |

SCP24-11.1-8.7-17.5 |

11.1 |

8.7 |

17.5 |

M12 |

7/16〃 |

– |

Solid |

SCP25-11.1-6.4-25.4 |

11.1 |

6.4 |

25.4 |

M10, M12 |

3/8〃 |

1/8〃 |

Solid |

SCP26-11.5-6.5-25 |

11.5 |

6.5 |

25 |

M10 |

3/8〃 |

1/8〃 |

Solid |

SCP27-12-9-18 |

12 |

9 |

18 |

M10 |

7/16〃 |

– |

Solid |

SCP28-12.7-3.2-50.8 |

12.7 |

3.2 |

50.8 |

M10 |

7/16〃 |

– |

Solid |

SCP29-13-9-25 |

13 |

9 |

25 |

– |

– |

– |

Solid |

SCP30-14-7-27.9 |

14 |

7 |

27.9 |

– |

– |

– |

Solid |

SCP31-14.3-7.9-28.6 |

14.3 |

7.9 |

28.6 |

M10,M12,M14 |

7/16〃 ,1/2〃 ,9/16〃 |

1/4〃 |

Solid |

SCP32-14.3-9-25.4 |

14.3 |

9 |

25.4 |

M10, M12, M14 |

7/16〃 ,1/2〃 ,9/16〃 |

1/4〃 |

Solid |

SCP33-15.1-10.3-25.4 |

15.1 |

10.3 |

25.4 |

M14, M16 |

1/2〃 ,9/16〃 |

– |

Solid |

SCP34-15.9-11.1-22.2 |

15.9 |

11.1 |

22.2 |

M14, M16 |

9/16〃 ,5/8〃 |

3/8〃 |

Solid |

SCP35-16.7-12.7-25.4 |

16.7 |

12.7 |

25.4 |

M16 |

5/8〃 |

3/8〃 |

Solid |

SCP36-17-13-25 |

17 |

13 |

25 |

– |

– |

– |

Solid |

SCP37-17.5-11.1-25.4 |

17.5 |

11.1 |

25.4 |

M14, M16, M18 |

5/8〃 |

3/8〃 |

Solid |

SCP38-18-14-20 |

18 |

14 |

20 |

– |

– |

– |

Solid |

SCP39-19.1-14.3-25.4 |

19.1 |

14.3 |

25.4 |

M18, M20 |

3/4〃 |

– |

Solid |

SCP40-19.1-14.3-14.3 |

19.1 |

14.3 |

14.3 |

M18, M20 |

3/4〃 |

– |

Solid |

SCP41-19.8-15.9-25.4 |

19.8 |

15.9 |

25.4 |

M20 |

3/4〃 |

1/2〃 |

Solid |

SCP42-20-15.5-16 |

20 |

15.5 |

16 |

M20 |

3/4〃 |

1/2〃 |

Solid |

SCP43-20.6-15.9-25 |

20.6 |

15.9 |

25 |

– |

– |

– |

Solid |

SCP44-22-16-25.4 |

22 |

16 |

25.4 |

– |

– |

– |

Solid |

SCP45-23.5-19-19.5 |

23.5 |

19 |

19.5 |

M22 |

7/8〃 |

– |

Solid |

SCP46-23.5-19.1-25.4 |

23.5 |

19.1 |

25.4 |

– |

– |

– |

Solid |

SCP47-23.5-20-10 |

23.5 |

20 |

10 |

– |

– |

– |

Solid |

SCP48-23.8-18.3-25.4 |

23.8 |

18.3 |

25.4 |

M22 |

7/8〃 |

– |

Solid |

SCP49-25.4-19.8-25.4 |

25.4 |

19.8 |

25.4 |

M22, M24 |

1〃 |

3/4〃 |

Solid |

SCP50-26-20-25 |

26 |

20 |

25 |

– |

– |

– |

Solid |

SCP51-27-23-25.4 |

27 |

23 |

25.4 |

M27 |

– |

– |

Solid |

SCP52-27.9-23.8-25.4 |

27.9 |

23.8 |

25.4 |

M30 |

11/8〃 |

– |

Solid |

SCP53-31-25-30-Z |

31 |

25 |

30 |

– |

– |

– |

Hollow |

SCP54-31.8-26.2-25.4 |

31.8 |

26.2 |

25.4 |

M33 |

11/4〃 |

– |

Solid |

SCP55-33.4-27-25.4 |

33.4 |

27 |

25.4 |

M33 |

11/4〃 ,13/8〃 |

1〃 |

Solid |

SCP56-34-27-25.4 |

34 |

27 |

25.4 |

– |

– |

– |

Solid |

SCP57-36.5-30.2-25.4 |

36.5 |

30.2 |

25.4 |

M36 |

13/8〃 |

– |

Solid |

SCP58-37-30-25.4 |

37 |

30 |

25.4 |

– |

– |

– |

Solid |

SCP59-38.9-31.8-25.4 |

38.9 |

31.8 |

25.4 |

M39 |

11/2〃 |

– |

Solid |

SCP60-39-31-25-Z |

39 |

31 |

25 |

– |

11/2〃 |

– |

Hollow |

SCP61-41.3-33.3-25.4 |

41.3 |

33.3 |

25.4 |

M39, M42 |

11/2〃 |

11/4〃 |

Solid |

SCP62-42.9-35.7-25.4 |

42.9 |

35.7 |

25.4 |

M42 |

– |

11/4〃 |

Solid |

SCP63-43-36-25-Z |

43 |

36 |

25 |

M42, M45 |

– |

13/8〃 |

Hollow |

SCP64-44.5-37.3-25.4 |

44.5 |

37.3 |

25.4 |

M48 |

– |

– |

Solid |

SCP65-46-38-25-Z |

46 |

38 |

25 |

– |

– |

– |

Hollow |

SCP66-46-38.1-25.4 |

46 |

38.1 |

25.4 |

M48 |

– |

11/2〃 |

Solid |

SCP67-50-41.3-25.4 |

50 |

41.3 |

25.4 |

– |

– |

11/2〃 |

Solid |

SCP68-52.4-44.5-25.4 |

52.4 |

44.5 |

25.4 |

M56 |

– |

– |

Solid |

SCP69-53-45-25-Z |

53 |

45 |

25 |

– |

– |

– |

Hollow |

SCP70-56-47.6-25.4 |

56 |

47.6 |

25.4 |

M56 |

– |

– |

Solid |

SCP71-62.7-50-25.4 |

62.7 |

50 |

25.4 |

M64 |

– |

2〃 |

Solid |

SCP72-63-50-25-Z |

63 |

50 |

25 |

M60, M62 |

– |

– |

Hollow |

SCP73-63.5-54-25.4 |

63.5 |

54 |

25.4 |

M64 |

– |

2〃 |

Solid |

SCP74-68.3-57.9-25.4 |

68.3 |

57.9 |

25.4 |

– |

– |

– |

Solid |

SCP75-75-61.9-34.9 |

75 |

61.9 |

34.9 |

– |

– |

2 1/2 |

Solid |

SCP76-88.9-76.2-38.1 |

88.9 |

76.2 |

38.1 |

– |

– |

3〃 |

Solid |

SCP77-101.6-82.6-38.1 |

101.6 |

82.6 |

38.1 |

– |

– |

– |

Solid |

SCP78-127-88.9-50.8 |

127 |

88.9 |

50.8 |

– |

– |

4〃 |

Solid |