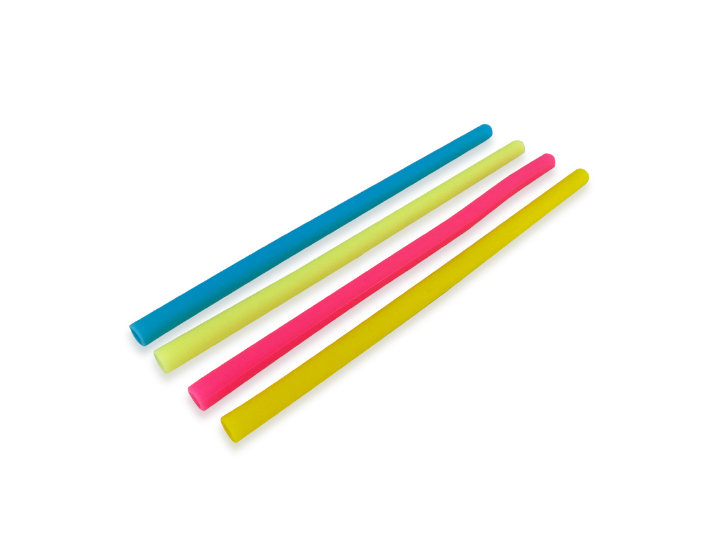

The Taiwan Ministry of Health and Welfare of the Executive Yuan announced that from July 2019, in four major places: public departments, public and private schools, department stores and shopping centers, and fast-food restaurants (about 8,000 businesses) shall not provide single-use plastic straws for in-house customers. There are various alternatives to plastic straw such as stainless-steel straws, glass straws, silicone straws, bamboo straws and so on, which are reusable straws. And for single-use, there are options such as paper straws, sugarcane straws, and so on. Silicone straws are a better choice than those made of stainless steel and glass because of the transparency, softness, and durability.

What is silicone?

The raw materials of silicone are mainly from natural ores. Food grade silicone that was extracted with high-purity is plasticizer and bisphenol A free, non-toxic, odorless with high and low temperature resistance, which is 100% safe to use and eco-friendly. Silicone consists mainly of silica, which is an amorphous product made of sodium silicate and sulfuric acid in silica. It is made into granular or beaded form after washing and processing minerals that exist in the nature. Due to its great chemical stability with high safety, non-toxic, and non-corrosive, silicone has been approved by the US FDA for use in the food and pharmaceutical industries. For example, the material of pacifiers is silicone.

Do not misunderstand silicone ≠plastic

Silicone products became popular about more than a decade ago, but are often mistaken as plastic products. Silicone products were created to replace polluting plastics and rubbers. The differences are:

- Plastic and rubber products release toxic substances when heated, have short lifespans, and they become hard and brittle after using them for a period of time.

- The raw material of silicone is mainly from natural ore, which can withstand high temperature of 230ºC, does not contain plasticizer and bisphenol A, is 100% eco-friendly that is safe and durable, and can greatly reduce resource consumption.

How to ensure the quality of silicone tubes?

The production method of silicone is similar to that of rubber that they both are traditional industries, which require a lot of labor. In general, rubber factories can produce silicone products. Due to the relocation of industries in Taiwan and the shortage of labor force, most of those who stay in Taiwan are small and medium-sized silicone rubber factories, serving Taiwanese enterprises with a small amount but diverse productions. When a mass production is required, it can only be produced by factories in China. There are not many factories in Taiwan that are specialized in the production of silicone tubes, and the output is also limited. Thus, most of the silicone tubes on the market that are sold in large quantities are made in China. As for which country’s silicone tubes are more guaranteed? It depends on whether the silicone factories can provide SGS inspection certificate for their silicone raw material, and most importantly, whether final products of silicone tubes have passed the inspection standards of Taiwan SGS.

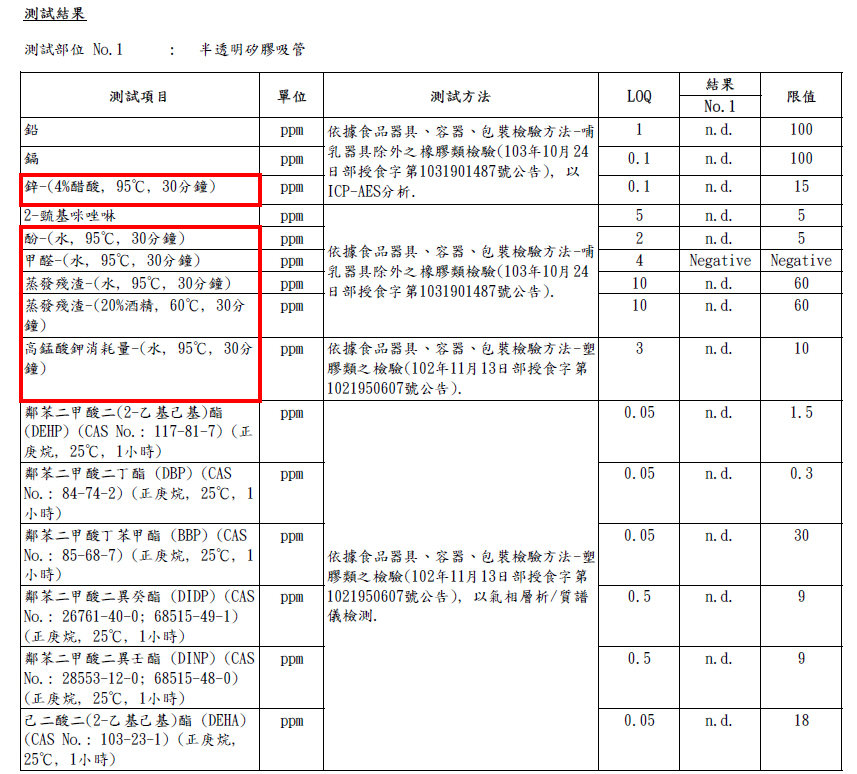

Dafeng Integrity – silicone tubes from our customized silicone factory have passed the tests of Taiwan SGS as shown in the following:

1.Four major inspection items for silicone tubes:

a.Rubber inspection (the inspections of silicone products in Taiwan refer to those for rubber products, which contain the plasticizer testing.)

b.U.S. FDA healthy standard inspection

c.Inspection of eight major heavy metals

d.Bisphenol A (BPA) inspection (silicone products in Taiwan do not have BPA specifications, this item refers to PPSU feeding bottle specifications.)

2.Other important inspection items:

a.High temperature resistance in 95ºC water detection (for high temperature hot drinks)

b.4% acidic acid in 95ºC detection (for acidic beverages)

c.Provide Chinese, English, and Chinese/English test reports (for letting the public understand)

d.Provide a QR code, which can be linked to the SGS online platform for browsing (for public inquiry)

Q: How much is the total cost of the four major inspection items for silicone tubes?

A: NT$ 46620 (tax included)

Q: Is the SGS inspection obligated by law/regulation?

A: No. (But this is the responsibility of the company)

Q: Whether or not silicone tubes in different sizes need to be inspected separately?

A: If the tubes are in the same batch, using the same material, in the same color, from the same supplier, but in different sizes, you can choose one for receiving the inspections.

Q: Whether or not silicone tubes in different colors need to be inspected separately?

A: Yes. (Products in different colors are made of different materials.)

Q: Whether or not silicone tubes in different batches need to be inspected separately?

A: Yes. (Theoretically yes, but in fact, there is no manufacturer has the ability to complete inspections for every single batch. The best we can do is to strengthen the process management.)

Q: Can silicone be decomposed in nature?

A: It can be decomposed naturally, however, silicone has great durability (this is also the reason why silicone is eco-friendly). The life of silicone is longer than that of humans, and it may take more than 100 years to decompose.

Q: Can silicone be thrown into the garbage truck?

A: the EPA replied that if there is a recycling label printed on the top of the product, it can be recycled by the resource recycling vehicle of EPA cleaning team. If not, it will be classified as general garbage and thrown into the garbage truck (to the incinerator).

(“Silicone” is extracted from natural ore. Pure Silicone has no toxic substance. It emits white smoke when burning that is odorless and non-toxic. After burning, it turns into white ashes. Thus, it can be directly discarded into garbage trucks and put into the incinerators without harming the environment.)

Q: Can silicone waste be recycled?

A: The scraps and wastes in the production process of the silicone rubber factory are recycled by special recycling factories (1 kilogram for NT$ N). Food grade silicone can no longer be used as a material for Food grade silicone products after recycling (it becomes a degraded product), which can only be used as a material for industrial-grade products. (Comparing with non-regenerated silicone material, the elasticity, extension and the tear strength of recycled silicone rubber are not as good as those of the original silicone rubber. At the same time, the hardness of recycled silicone rubber is also relatively high, and slight deformation can also be found after using for a period of time.)

Q: Can a used and dirty silicone tube be recycled?

A: At present, silicone tubes are not yet widely used, and there is no fix recycling point for used silicone tubes. We look forward to a relevant guidance and plan of recycling silicone products for recycling manufacturers from the government.

Silicone tubes meet the requirement of Taiwan SGS inspection standards:

| No | 檢測項目 | 檢測內容 | 結果 |

| 1 | Rubber 橡膠檢測

-含塑化劑檢測 -水耐95度High溫檢測 -醋酸4%之95度檢測 |

鉛、鎘、鋅-(4%醋酸, 95℃, 30分鐘)

2-巰基咪唑啉 酚-(水, 95℃, 30分鐘) 甲醛-(水, 95℃, 30分鐘) 蒸發殘渣-(水, 95℃, 30分鐘) 蒸發殘渣-(20%酒精, 60℃, 30分鐘) High錳酸鉀消耗量-(水, 95℃, 30分鐘 鄰苯二甲酸二(2-乙基己基)酯(DEHP)(正庚烷, 25℃, 1小時) 鄰苯二甲酸二丁酯 (DBP) (CASNo.: 84-74-2) (正庚烷, 25℃, 1 小時) 鄰苯二甲酸丁苯甲酯 (BBP) (CASNo.: 85-68-7) (正庚烷, 25℃, 1 小時) 鄰苯二甲酸二異癸酯 (DIDP) (CASNo.: 26761-40-0; 68515-49-1) (正庚烷, 25℃, 1小時) 鄰苯二甲酸二異壬酯 (DINP) (CASNo.: 28553-12-0; 68515-48-0) (正庚烷, 25℃, 1小時) 己二酸二(2-乙基己基)酯 (DEHA)(CAS No.: 103-23-1) (正庚烷, 25℃, 1小時) 重金屬(以鉛計)-(4%醋酸, 95℃,30分鐘) 鄰苯二甲酸二(2-乙基己基)酯(DEHP) 鄰苯二甲酸二丁酯 (DBP) 鄰苯二甲酸丁苯甲酯 (BBP) 鄰苯二甲酸二正辛酯 (DNOP) 鄰苯二甲酸二異壬酯 (DINP) 鄰苯二甲酸二甲酯 (DMP 鄰苯二甲酸二異癸酯 (DIDP) 鄰苯二甲酸二乙酯 (DEP) |

全部未檢出 |

| 2 | FDA(美國)衛生標準檢測 | 總萃取物 (水, 迴流, 前7小時)

總萃取物 (水, 迴流, 接續2小時) 總萃取物 (正己烷, 迴流, 前7小時) 總萃取物 (正己烷, 迴流, 接續2小時) |

通過 |

| 3 | 八大重金屬檢測 | 銻、砷、鋇、鉻、鎘、鉛、汞、硒 | 全部未檢出 |

| 4 | pairs酚A(BPA)材質檢測 | pairs酚A(BPA) | 全部未檢出 |

Dafeng Integrity – silicone tubes from our customized silicone factory have passed the tests of Taiwan SGS