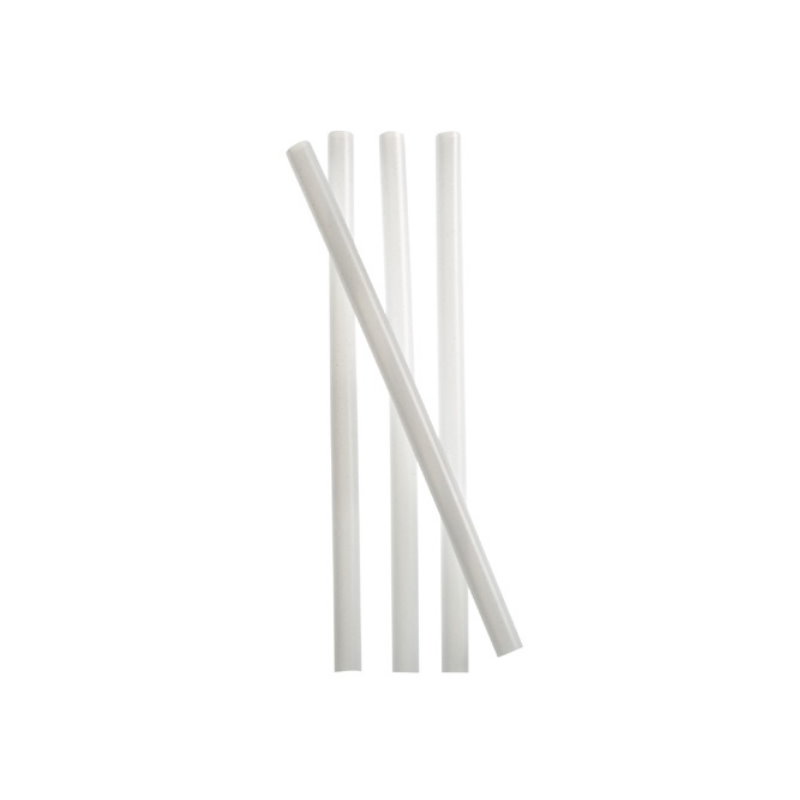

Food grade silicone tubes are made of imported silicone materials with the scientific production technology, which gives this product a wider range of adaptability. Our Food grade silicone tubes have several advantages of high transparency, odorless, non-yellowing, non-frosting, and so on. Especially, we solve the problems of frosting in black rubber tubes and color fading in blue products.

Food grade silicone is an additive silicone. High-quality transparent Food grade silicone with high transparency and stability has high temperature resistance that can reach 230℃ and can also be heated without deforming in a sealing environment. Food grade silicone is made of high-quality imported Food grade silicone raw material with the scientific formula and advanced technology. This product has the characteristics of softness, high temperature resistance, stable, and so on. People nowadays pursuing healthy diet has gradually replaced food grade plastic with Food grade silicone.

Main features of Food grade silicone tubes:

1.Non-toxic, odorless, high transparency, non-yellowing;

2.Soft, good elasticity, kink resistance without deforming;

3.Non-cracking, long service life, good thermal stability;

4.Has higher tear strength and superior electrical properties;

5.It is more suitable for the silicone tube of food machinery;

Main usages of Food grade silicone tubes:

1.The straws and ducts on baby bottles, etc.;

2.Electrical equipment and other casings and profiles;

3.Tube products for food;

4.Connecting pipe for food machinery;

5.Connecting pipes and ducts for drinking fountains, coffee pots, children’s suction cups, etc.

Features of Food grade silicone tubes:

1. Food grade silicone is a kind of eco-friendly silicone that is non-toxic, odorless with high transparency;

2. Soft, good elasticity, kink resistance without deforming;

3. Non-cracking, long service life, good thermal stability;

4. Has higher tear strength and superior electrical properties;

5. When placing the tube at room temperature, it can be non-yellowing, non-frosting, non-whitening, and non-fading. When placing the tube in the water for a long time, it can be non-scale-forming and odorless.

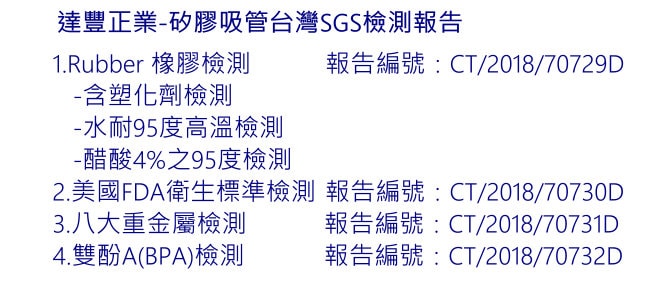

Dafeng Integrity – silicone tubes from our customized silicone factory have passed the tests of Taiwan SGS as shown in the following:

1.Four major inspection items for silicone tubes:

a.Rubber inspection (the inspections of silicone products in Taiwan refer to those for rubber products, which contain the plasticizer testing.)

b.U.S. FDA healthy standard inspection

c.Inspection of eight major heavy metals

d.Bisphenol A (BPA) inspection (silicone products in Taiwan do not have BPA specifications, this item refers to PPSU feeding bottle specifications.)

2.Other important inspection items:

a.High temperature resistance in 95ºC water detection (for high temperature hot drinks)

b.4% acidic acid in 95ºC detection (for acidic beverages)

c.Provide Chinese, English, and Chinese/English test reports (for letting the public understand)

d.Provide a QR code, which can be linked to the SGS online platform for browsing (for public inquiry)

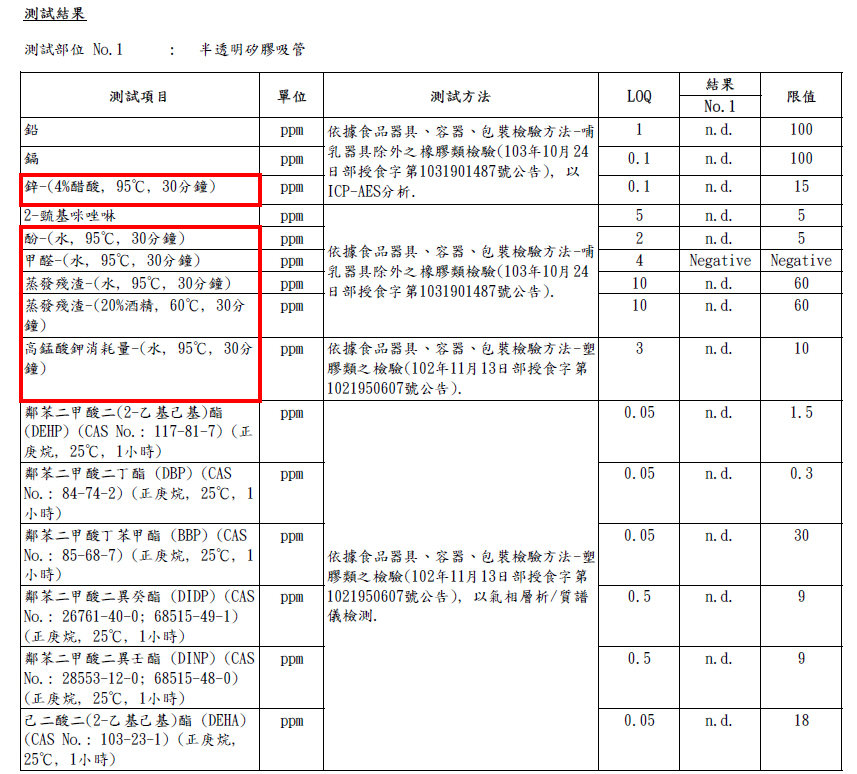

| No | 檢測項目 | 檢測內容 | 結果 |

| 1 | Rubber 橡膠檢測

-含塑化劑檢測 -水耐95度High溫檢測 -醋酸4%之95度檢測 |

鉛、鎘、鋅-(4%醋酸, 95℃, 30分鐘)

2-巰基咪唑啉 酚-(水, 95℃, 30分鐘) 甲醛-(水, 95℃, 30分鐘) 蒸發殘渣-(水, 95℃, 30分鐘) 蒸發殘渣-(20%酒精, 60℃, 30分鐘) High錳酸鉀消耗量-(水, 95℃, 30分鐘 鄰苯二甲酸二(2-乙基己基)酯(DEHP)(正庚烷, 25℃, 1小時) 鄰苯二甲酸二丁酯 (DBP) (CASNo.: 84-74-2) (正庚烷, 25℃, 1 小時) 鄰苯二甲酸丁苯甲酯 (BBP) (CASNo.: 85-68-7) (正庚烷, 25℃, 1 小時) 鄰苯二甲酸二異癸酯 (DIDP) (CASNo.: 26761-40-0; 68515-49-1) (正庚烷, 25℃, 1小時) 鄰苯二甲酸二異壬酯 (DINP) (CASNo.: 28553-12-0; 68515-48-0) (正庚烷, 25℃, 1小時) 己二酸二(2-乙基己基)酯 (DEHA)(CAS No.: 103-23-1) (正庚烷, 25℃, 1小時) 重金屬(以鉛計)-(4%醋酸, 95℃,30分鐘) 鄰苯二甲酸二(2-乙基己基)酯(DEHP) 鄰苯二甲酸二丁酯 (DBP) 鄰苯二甲酸丁苯甲酯 (BBP) 鄰苯二甲酸二正辛酯 (DNOP) 鄰苯二甲酸二異壬酯 (DINP) 鄰苯二甲酸二甲酯 (DMP 鄰苯二甲酸二異癸酯 (DIDP) 鄰苯二甲酸二乙酯 (DEP) |

全部未檢出 |

| 2 | FDA(美國)衛生標準檢測 | 總萃取物 (水, 迴流, 前7小時)

總萃取物 (水, 迴流, 接續2小時) 總萃取物 (正己烷, 迴流, 前7小時) 總萃取物 (正己烷, 迴流, 接續2小時) |

通過 |

| 3 | 八大重金屬檢測 | 銻、砷、鋇、鉻、鎘、鉛、汞、硒 | 全部未檢出 |

| 4 | pairs酚A(BPA)材質檢測 | pairs酚A(BPA) | 全部未檢出 |

如何判斷檢驗報告真的為台灣SGS檢測單位所發出報告?

1.看其報告號碼編號是否為台灣編號?

2.看其檢驗證明章是否為TAIWAN?

3.看其檢驗報告詳細內容是否符合四大檢測項目?

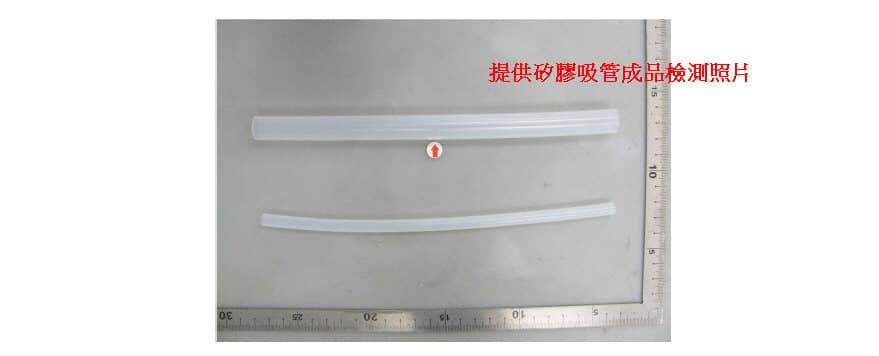

4.看其檢測報告是否有附矽膠吸管成品檢測照片?