Silicone: Also known as silicone rubber, silicone is a highly active adsorption material and is an amorphous substance with a chemical formula of mSiO2·nH2O. It is insoluble in water and any solvent, non-toxic and odorless, chemically stable, and does not react with any substances except strong alkali and hydrofluoric acid.

Silicone rubber refers to the rubber whose main chain is composed of alternating silicon and oxygen atoms, and two organic groups are usually connected to the silicon atom. Ordinary silicone rubber is mainly composed of silicon-oxygen chains containing methyl groups and a small amount of vinyl groups. The introduction of phenyl can improve the high and low temperature resistance of silicone rubber, and the introduction of trifluoropropyl and cyano groups can improve the temperature and oil resistance of silicone rubber. Silicone rubber has good low temperature resistance and in general, it can still work at -55°C. After the introduction of phenyl, it can reach -73°C. The heat resistance of silicone rubber is also very outstanding. It can work for a long time at 180°C, and can withstand a few weeks or longer even if it is slightly higher than 200°C. It can withstand high temperatures above 300°C instantaneously. Silicone rubber has good air permeability and oxygen transmission rate is the highest among synthetic polymers. In addition, silicone rubber has outstanding properties of being physiologically inert that does not cause coagulation, which is widely used in the medical field.

Silicone rubber is divided into thermal vulcanization type (high temperature vulcanization silicone rubber HTV), room temperature vulcanization type (RTV), and room temperature vulcanization type is divided into polycondensation reaction type and addition reaction type. High temperature silicone rubber is mainly used to produce various silicone rubber products, while room temperature silicone rubber is mainly used as adhesive, potting material or mold. The thermal vulcanization type is the most commonly used type, and is divided into methyl silicone rubber (MQ), methyl vinyl silicone rubber (VMQ, the most commonly used and producd brand), and methyl vinyl phenyl silicone rubber PVMQ (low temperature resistance, radiation resistance), and others include nitrile butadiene rubber, fluorosilicone rubber, and so on.

Silicone can be divided into two categories: organic silicone and inorganic silicone according to its properties and components.

- Organic silicone is an organosilicon compound. Silicone is mainly divided into four categories: silicone rubber, silicone resin, silicone oil, and silane coupling agent.

- Inorganic silicone is divided into: macroporous silicone, coarse-pored silicone, B-type silicone, and fine-pored silicone according to the size of its pore size.

What are the differences between silicone and plastic PVC?

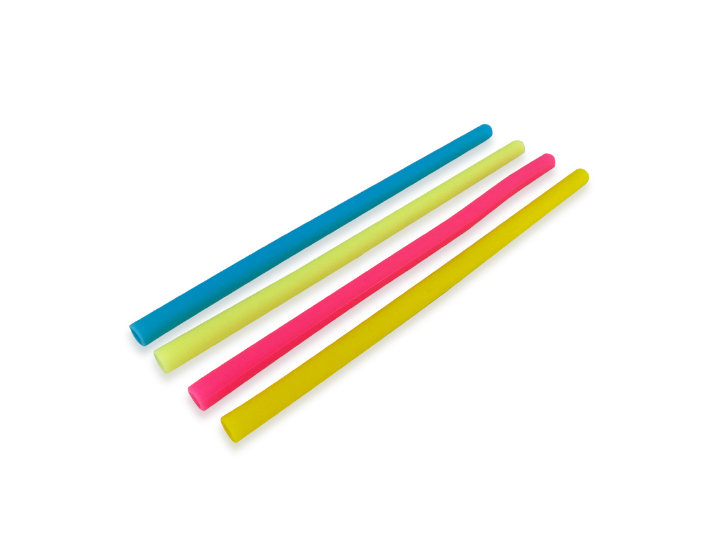

Silicone (high quality, good elasticity)

Smooth, soft, seamless surface ensures good sealing performance; can be autoclaved or gamma ray sterilized for repeated use; odorless; good chemical resistance; has operating temperatures from -40°C to 230°C.

Plastic PVC (cheap, wear-resistant)

PVC (poly vinylchloride) refers to polyvinyl chloride, a common plastic commonly used in various tubing, artificial leather, and transparent sandals. It is the most used plastic in construction. Rigid PVC has a density of 1.38-1.43g/cm3, high mechanical strength and good chemical stability. The operating temperature range is generally between -15°C to 55°C, which is suitable for producing plastic doors and windows, sewer pipes, wire ducts, and so on. After PVC is heated