Die-cutting processing technology is used in many industries, especially the surface processing of various printed matters, it is an important way to ensure that the packaging design can be well reflected. Effective decoration processing of various levels of artworks, trademarks, cartons can play a very effective role in the decoration of packaging. Moreover, the process of die-cutting has a very important influence on enhancing the artistic effect in printed matter. At present, die-cutting has become the most popular process. However, when the paper prints are die-cut, there will be a situation of low precision. How do we solve and prevent when facing such a situation?

First, the effect of the low precision of die-cutting

While die-cutting paper products or printed matter, if there is a certain deviation in the die-cutting process, it will lead to the situation that the finished product cannot be made and synthesized in a tight fit, which will have an important impact on the quality of the product. The effect of measuring the die-cutting process is mainly reflected in whether the precision of the die-cutting process is sufficient. If the die-cutting process accuracy is not high enough, the qualified rate of the processed products will also be greatly affected.

Second, the reasons and countermeasures for the low precision of die-cutting

1. Mechanical reasons

In the process of die-cutting, the reasonable operation of the machine and whether it can operate effectively is one of the main factors affecting the precision of die-cutting. This includes whether the intermittent mechanism of the die-cutting machine is excessively worn, whether the distance between the front and rear positioning swing frames is too narrow, whether the positioning of the upper and lower die-cutting plates is accurate, and so on. Therefore, it is the main solution to ensure high precision when inspecting and maintaining machinery frequently.

2. Environmental impact

If the cardboard is stretched or deformed, it will also affect the precision of the die-cutting process. Therefore, it is strived to ensure the uniformity of the processing environment and select the appropriate paper to ensure the precision of the processing.

3. Reasons of the operator

Whether the operator strictly follows the production process is also one of the main factors affecting the accuracy.

Through the above introduction on the problems that can affect the precision of die-cutting, it is hoped that the precision of die-cutting can be effectively improved, and thereby ensuring the quality of processing.

Dafeng Integrity Corporation is a professional silicone factory and company focusing on the production, promotion and application of silicone products. The production process is certified by the ISO9001 and TS 16949 international quality management systems. Our silicone products have the certifications of ROHS. LFGB, FDA, etc. The production process of Dafeng Integrity silicone factory is shown in the following:

01-Air shower

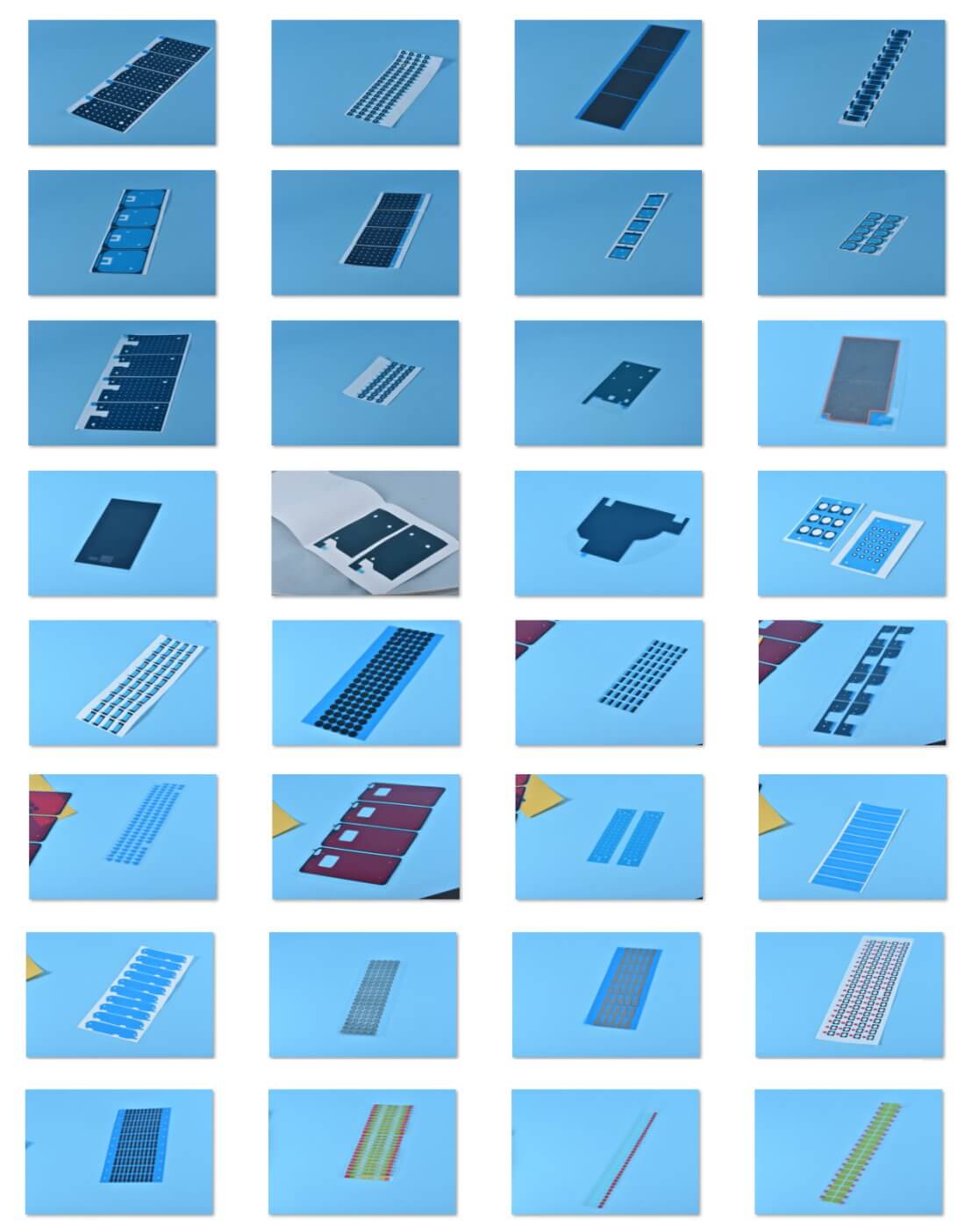

02-Round knife rotary die cutting machine

03-Die cutting – round knife

04-Die cutting machine workshop

05-Flatbed die cutting

06-Die cutting inspection platform

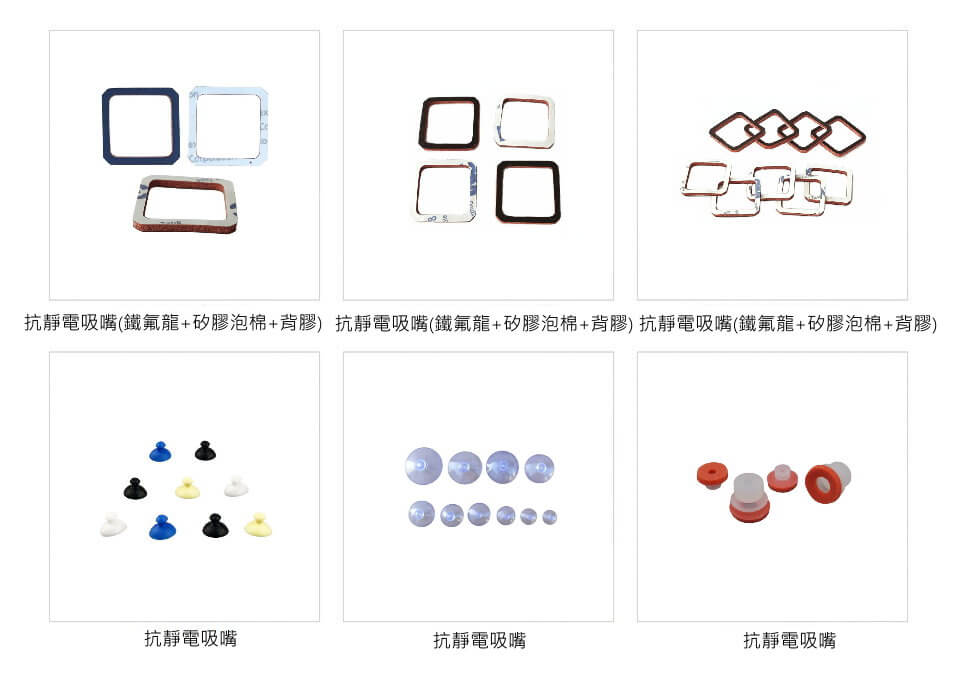

Silicone nozzle

Die-cut, adhesive-backed products